Description

I am sorry to say our shoe manufacturer is out of business, and we no longer see carrying them. We are liquidating the remaining inventory at below-cost prices. There are NO RETURNS ON LIQUIDATED ITEMS.

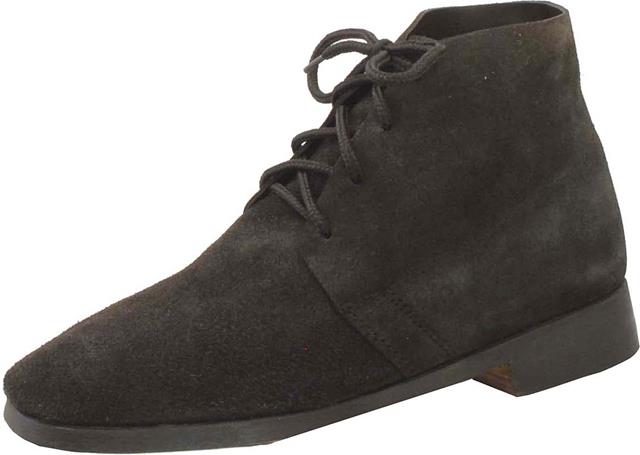

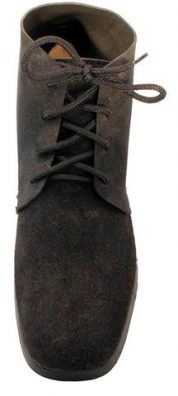

Rough out Brogan by Fugawee. When you want a good shoe so your feet don’t hurt, no break in time, Vegetable tanned upper, oak tanned inner and outer sole. McKay stitched not Goodyear welted. This is a well built sturdy shoe. Heel plates and hobnails will extend the life of the sole.

The Army used the term “Jefferson”. The reason goes back to Thomas Jefferson:

During the French Revolution, large, fancy shoe buckles were considered the mark of the Aristocrats.

Shortly, wearing any shoe buckles at all could cause your head to leave your body. Shoe buckles quickly went out of style in France.

In the United States, Thomas Jefferson was a strong supporter of the French Revolution so, at his inauguration in 1801 he wore laced-up shoes.. This set a fashion. All laced shoes soon were called “Jefferson Shoes.”

The term “Jefferson” continued to mean laced shoes until the early twentieth century. “Bootee” is a diminutive of “Boot” and signifies a short boot. “Brogan” is derived from “Brogue”, an English term for a rugged shoe that almost covered the ankle as opposed to a shoe which was lower and a boot which was higher.

Facts about Original Civil War Shoes

Before the war, almost all army shoes were made at Susquehanna Arsenal. The pieces were cut out in the arsenal and then “farmed out” to independent workers who put them together in their homes on piecework basis It was the same system that was used for uniforms.

Historically, shoe uppers always had been considered women’s work and this may be all that was done by the home workers but it is possible that the welting and sole stitching was done at home as well.

The largest pair of bootees on record still exists. They are smooth side out, size 17. Three pairs were specially manufactured for a large Swedish draftee. The shoes never reached him. A target of his size was just too tempting and the Confederates killed him before his custom-made shoes got to him. One pair of his shoes remains in a museum at Susquehana.

Fugawee calls our Northern or Federal shoe a Contract Bootee because, contrary to pre-war practice, Army footwear was built by contractors. Naturally, there were slight variations in the shoes issued to the Northern troops.

We have a letter dated January 1862 from Colonel Crossman, Assistant Quartermaster General describing the purchase of 1,102,700 pairs of boots and bootees from contractors all over the North. Contracts were as large as 120,000 pairs from one manufacturer at Sing Sing, NY (did they have the prison then?) or as small as 300 pairs from another factory in Pennsylvania. The shoes apparently included work shoes already on hand. They had been manufactured on lasts (the forms on which shoes are built) already in the factories. You may be sure that contractors produced variations in design and fit.. This is borne out in the Congressional hearings early in 1862. Some of the testimony is hilarious.

One manufacturer, faced with the fact that he had supplied shoes that foot soldiers wore out in three weeks replied, “But those shoes were supposed to go to the Cavalry.” So help me, it is in the Congressional Record of the Washburn Committee..

In early 1862 Crossman reported his purchases to Congressman E.B. Washhburn, Chairman of the House Committee to Inquire into Government Contracts (Page 1569, Record of the 37th Congress, 2nd Session) click to read the letter and apologized for having accepted a small quantity of pegged bootees which had been accepted only because of the urgency of the war. Regulations called for sewn shoes but cheap work shoes for the immigrant trade and those for the plantation (slave) trade had been pegged together since a labor-saving machine that set nine pegs to the inch came into use.

Which is correct, pegged or sewn?

The army did everything it could to force the contractors to deliver sewn shoes. While a pair of sewn shoes brought the contractor $1.80 to $2.00 per pair, the Government would pay only $1.25 for pegged shoes. With Cavalry boots the prices were $3.25 for sewn and $2.50 for pegged. The Army accepted only 265 pairs of pegged of cavalry boots out of 183,997 pairs purchased by Colonel Crossman.

In a total of 1,102,700 pairs of shoes and boots purchased by Col. Crossman only 5.43% were pegged. The Colonel felt that he had to explain that he had bought the inferior pegged shoes only because of the exigencies of the war, even though they cost the Gov’t one third less.

Here is a picture of the sole of an original Civil War issue pegged boot. The split-apart pegs are diamond-shaped (remember the machine?) and are in two staggered rows that total nine pegs pr inch.  Although it is hard to tell, this is a left/right shoe.

Although it is hard to tell, this is a left/right shoe.

The shank is riveted in place and the heel has a close-set row of cut nails to extend wear. The boot is machine pegged, nine pegs to the inch.

No, that is not stitching, it is two rows of pegs. They are staggered for strength and to get as many pegs in the row as possible. Note the rivets on the shank and the close-set nails in the heel.

Forty percent of Civil War shoes were made on a pegging machine invented in 1838, It was much like a two needle sewing machine and almost as fast. The first station was an awl which made a hole, then the second station drove a peg into the hole.

This machine took a block of wood that had been cut across the grain and was of a thickness equal to length of the pegs. The end grain was scored in both directions, making a “card” full of diamond points. The card was then split by the machine to free the hundreds of pegs. These fed directly into the next step in the machine which inserted them in the shoes.

One of the big differences between the nine-to-the-inch machine-pegged shoes actually used in the Civil War and the three-or-four-to-the-inch pegging seen on Sutlers’ Row is the fact that machine-set pegs were driven all the way through the leather until they were flush with the sole. The points that went into the interior of the shoe were then cut off with special tools before the insole was glued in. Those pegs were square and straight-sided all through the leather.

Most of today’s reproduction shoes are made with round, polished pegs which are actually made to hold the shanks of modern cowboy boots. The pointed ends of the pegs are driven in only until they encounter the metal form inside the shoe. When the points of the pegs reach the metal, they are cut off on the outside: This means that the smooth, pointed peg is in a tapered hole. Thus, the shoes have three or four round, polished and tapered pegs instead of nine straight-sided, split-off pegs to the inch . The shoe is held together mainly with glue. The pegs are mostly cosmetic.

Fugawee made “pegged” shoes until our research showed that the sewn shoes were not only appropriate, but had been preferred by the military.

About forty percent of all boots and brogans purchased by the US Army during the Civil War were constructed with the less expensive pegging process.

During the days of the Soviet Bloc, the East Germans and Poles used some machine-pegged boosts in their armies. I don’t know where you would find a pegging machine today. Fugawee Jefferson bootees are all sewn as per the basic military regulations during of the Civil War. Fugawee Jefferson bootees are built on lasts taken directly from an 1865 boot.

Our standard guarantee : Return re-saleable shoes for proper size or refund. On size changes, we pay the freight back to you. If the shoes have been in use and you find any problems in manufacture, materials, or if the shoe breaks down, call us. For small problems, we’ll tell you to have it fixed in your home town and send us the bill. If it seems more serious, send the shoes back and we’ll either repair or replace them. We have had this same guarantee for sixteen years. It is just like the LL Bean guarantee. We can do this because our Mexican factory also makes shoes for LL Bean.

Reviews

There are no reviews yet.